By Helius Roofing & Construction

When constructing a metal building, one of the most important factors to consider is the gauge of the metal. The term “gauge” refers to the thickness of the metal, and it plays a critical role in the durability, strength, and overall performance of your building. Whether you’re constructing a garage, warehouse, barn, or residential metal structure, understanding metal building gauges will help you make informed decisions about your project.

In this comprehensive guide, Helius Roofing & Construction will explain everything you need to know about metal building gauges, their significance, and how to choose the right gauge for your construction project.

What Is a Metal Building Gauge?

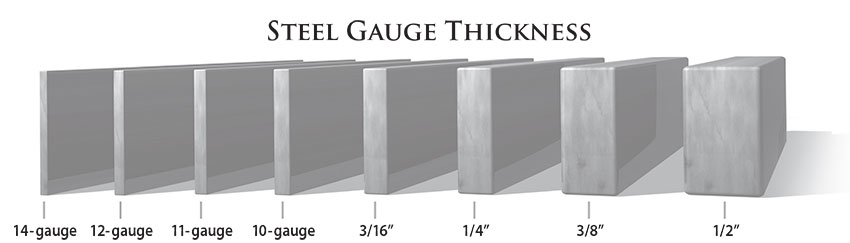

The gauge of a metal refers to its thickness. Interestingly, the gauge system works inversely, meaning the lower the number, the thicker the metal. For example, 12-gauge steel is thicker and stronger than 22-gauge steel. This system is used universally to indicate the thickness of metal sheets, panels, and structural components.

Gauge vs. Thickness

While the gauge number is an indicator of the metal’s thickness, it’s important to note that the actual measurement can vary slightly depending on the type of metal. For example, the thickness of 12-gauge steel is approximately 0.1046 inches, whereas 14-gauge steel is about 0.0747 inches thick. Each gauge number corresponds to a specific thickness, and these slight differences can have a significant impact on the strength and durability of your building.

Why Are Metal Gauges Important?

The gauge of the metal you choose will influence various aspects of your metal building, including its strength, durability, cost, and even energy efficiency. Selecting the right gauge ensures that your building can withstand local weather conditions, support its intended load, and provide long-term performance.

1. Structural Integrity

Thicker metal (lower gauge numbers) provides greater structural integrity. This is particularly important in regions that experience heavy snow, strong winds, or other extreme weather conditions. A metal building with a thicker gauge will be more resilient and less prone to damage from these environmental factors.

2. Resistance to Damage

Thicker metal gauges are less susceptible to dents, dings, and damage caused by impacts. For example, if your building is located in an area where hailstorms are common, choosing a lower gauge metal (thicker) will help prevent damage to the exterior panels. Thicker gauges also provide more protection against potential impacts from tools, equipment, or vehicles.

3. Longevity

Thicker metal is generally more resistant to corrosion, warping, and other forms of wear and tear. A building constructed with a lower gauge metal will last longer and require less maintenance over time, making it a more cost-effective choice in the long run.

4. Insulation and Energy Efficiency

Although metal gauges are not directly related to insulation, thicker metal can indirectly improve energy efficiency. Thicker panels can help reduce heat transfer and provide a more stable interior environment. Additionally, thicker metal panels create fewer gaps or seams, which minimizes air leakage and helps keep your building better insulated.

5. Cost

The cost of metal materials increases as the gauge number decreases. Thicker metal requires more material, which translates to higher manufacturing and shipping costs. Therefore, choosing a thicker gauge for your building may be more expensive upfront but can lead to savings on maintenance, repairs, and energy costs over time.

Common Metal Building Gauges

Metal building components, including the roof, walls, and framing, are available in different gauges. The most common gauges used in metal construction range from 12-gauge to 29-gauge. Each gauge has its ideal applications, and choosing the right one depends on factors such as climate, building size, and intended use.

12-Gauge Steel

12-gauge steel is one of the thickest and strongest options available for metal buildings. It is commonly used for structural elements like the framing and support columns, especially in areas with extreme weather conditions. Metal buildings made from 12-gauge steel are highly durable, able to withstand heavy loads, and provide excellent resistance to impacts and environmental wear. However, because of its thickness, 12-gauge steel is also one of the most expensive options.

Ideal Uses

- Industrial warehouses

- Agricultural buildings

- Garages in high-wind or heavy-snow areas

- Heavy-duty commercial buildings

14-Gauge Steel

14-gauge steel is slightly thinner than 12-gauge but still offers excellent strength and durability. This gauge is the most commonly used for metal building framing and is often chosen for commercial and residential applications. 14-gauge steel strikes a balance between strength, affordability, and ease of construction.

Ideal Uses

- Commercial buildings

- Residential garages and workshops

- Small warehouses

- Storage units

26-Gauge Steel

26-gauge steel is frequently used for metal roofing and wall panels. While thinner than 14- or 12-gauge, 26-gauge panels still offer good protection and are highly durable when installed properly. 26-gauge metal is suitable for a variety of building applications, from small sheds to large industrial facilities, and it offers better resistance to environmental conditions compared to thinner gauges like 29-gauge.

Ideal Uses

- Roofing panels

- Wall panels

- Carports

- Small to medium-sized storage buildings

29-Gauge Steel

29-gauge steel is the thinnest option commonly used in metal buildings. While more affordable, it is not as strong or durable as lower gauge metals. This gauge is typically used for smaller buildings that do not require heavy-duty structural support. For climates with mild weather conditions, 29-gauge steel can be a cost-effective option for projects like sheds, barns, or garages. However, it may not hold up well in areas with extreme weather or high wind loads.

Ideal Uses

- Storage sheds

- Carports

- Barns

- Budget-friendly residential garages

Choosing the Right Gauge for Your Metal Building

The choice of metal gauge for your building will depend on several factors, including your budget, local climate, the building’s intended use, and the type of loads it will need to support. Here are some key considerations when deciding on the right metal gauge:

1. Climate Conditions

If you live in an area that experiences heavy snow, strong winds, or hail, it’s essential to choose a thicker gauge metal for both the framing and the roof panels. Thicker metal provides better protection against the elements and can prevent damage during severe weather events. For example, in high-wind regions, 12-gauge or 14-gauge steel may be necessary to ensure your building can withstand the forces of nature.

2. Building Size and Use

The size and intended use of your metal building will also affect your gauge choice. Larger buildings that need to support heavy equipment, machinery, or other loads will require thicker metal for both the structure and the roofing. For smaller buildings or sheds used for storage, a thinner gauge like 26-gauge or 29-gauge may be sufficient.

3. Long-Term Durability

If you’re looking for long-term durability and minimal maintenance, it’s worth investing in a lower gauge metal. While the upfront cost may be higher, thicker metal will last longer and provide better protection against rust, corrosion, and impact damage.

4. Budget

Of course, your budget will also play a role in your gauge decision. Thicker metal costs more, so if you’re working with a limited budget, you may need to strike a balance between strength and affordability. Consider the climate, the building’s purpose, and the potential long-term savings when making your decision.

Conclusion

Choosing the right metal gauge is a crucial step in constructing a durable, long-lasting metal building. The gauge you select will directly affect your building’s structural integrity, resistance to damage, longevity, and overall performance. At Helius Roofing & Construction, we can help you choose the right materials and gauge for your specific project, ensuring that your metal building is built to withstand the elements and serve you well for years to come.

Whether you’re planning a small residential garage or a large industrial facility, our team of experts is here to guide you through the process. Contact Helius Roofing & Construction today to learn more about how we can assist you with your metal building construction needs.